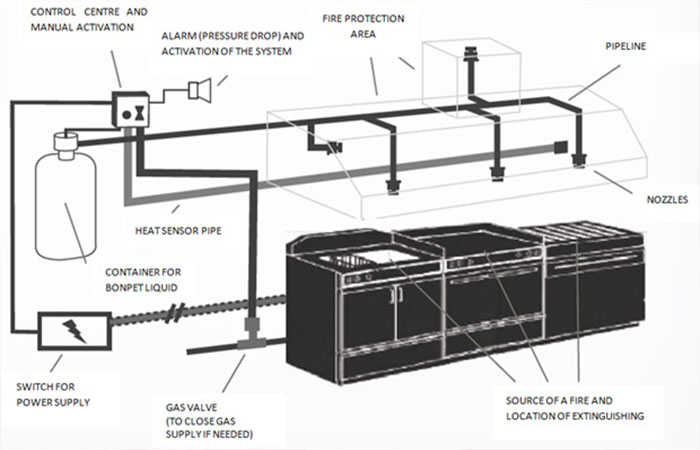

Kitchen Fire Suppression System

Self-activated, effective and easy to use for extinguishing fires in kitchens or smaller flammable risky areas.

Kitchen Fire Suppression System is suitable for extinguishing fires of classes A, B, F and it has great effect at extinguishing with a low amount of liquid Bonpet.

Suitable for :

Home, Apartment

Small Offices

Public amenities

Industrial facilities

Engineering facilities

Function

It functions as a special pipe that acts like a heat detector. The pipe is flexible and elastic and it can be installed everywhere. On one end the pipe is connected to a special valve with a trap, on the other end to a manual trigger. The pipe is under the pressure of 18 bars, diameter is 6 mm. The pipe transforms and activates at the temperature of 160-180°C. In case of a fire high temperature and flames cause the explosion of the pipe which leads to a drop of a pressure in the pipe causing self- activation and extinguishing a fire.

Advantages

- No false alarms, system only activates when the temperature rises.

- Does not cause any damages during the fire extinguishing and its remaining components are easily cleaned.

- Environmentally friendly.

- Slovenian product.

- Unlimited product life expectancy with 1-year warranty.

- Extinguishing without sealing a premises (in comparison when extinguishing with CO2).

- The extinguishing is not subject to prior evacuation of staff.

- It creates a layer on surface to prevent another ignition.

- Maintenance is not technically difficult.

- Unlimited options for detecting and consequently extinguishing a fire in the early stages.

- Easy to install the flexible pipes for detecting the fire; the fire can be detected on all the locations with high stage of fire hazard, like on inaccessible locations.

- No outside factor can trigger the detector (like vibration, shock, high concentration of oil, fat or dust).

- Source and voltage cannot trigger the detector.

Technical characteristics

- Volume of 6l reservoir: maximum of 5 pouts, the distance between pouts must be 80 cm, and the combined length must not exceed 4 m.

- Volume of 9l reservoir: maximum of 7 pouts, the distance between pouts must be 80 cm, and the combined length must not exceed 6 m.

- Volume of 12l reservoir: maximum of 9 pouts, the distance between pouts must be 80 cm, and the combined length must not exceed 8 m.

- Reservoir must be under constant pressure of 16 bars (at the temperature of 20°C).

- Working temperature of the system is from 0°C to 60°C.

- Propellant is nitrogen (N2).

- Piping and nozzles must be installed above a kitchen block and in the catch drain canals. Piping, dimension and location have to be certified by registered engineer.

Option of manual activation

It can be triggered by pressing on an activation button at the end of the flexible pipe. A component of the activation button is a manometer that measures the pressure in the pipe.

Pipeline

Behind the tank is a vent DN15 and behind of that vent, is a pipeline made of copper or galvanized iron or stainless steel, depending if it is installed indoor or outdoor. Pipes must be tested with a pressure test of 20 bars.